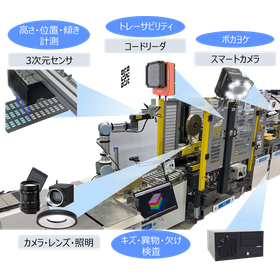

Image inspection device

You can conduct inspections without putting a burden on the work!

● The computer functions are equipped, and the operation is easy. ● It is space-saving and can be installed easily anywhere, allowing for mobility. ● The unit can be easily attached to existing devices. ● It can be introduced at a low cost. ● It can be used in either vertical or horizontal winding by simply changing the installation direction. ● Depending on the product pitch, it can support up to 3000 spm. ● You can choose from 8 types of CCD cameras, including a 2-megapixel type.

- Company:プレス技術研究所 本社営業部

- Price:Other

![[AI Image Inspection Case] Inspection of Electronic Circuit Boards](https://image.mono.ipros.com/public/product/image/ec7/2001457840/IPROS9633153901718271627.png?w=280&h=280)

![[Equipment and Production Achievements] Laser Engraving, Image Inspection Machine](https://image.mono.ipros.com/public/product/image/091/2000447078/IPROS40894577410707365851.jpeg?w=280&h=280)